How to Choose the Best Ceramic Bearing Bottom Bracket for Your Bike

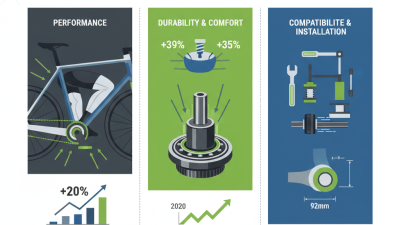

The choice of a ceramic bearing bottom bracket is crucial for cyclists seeking to enhance their bike's performance and longevity. Ceramic bearings have gained significant attention in the cycling community due to their lower friction properties and increased durability compared to traditional steel bearings. According to a recent report from the Cycling Performance Review, utilizing a ceramic bearing bottom bracket can reduce rolling resistance by up to 50%, translating into improved efficiency and speed for cyclists. This performance can be particularly beneficial in competitive settings, where every second counts.

Moreover, the robustness of ceramic bearings allows them to withstand harsher conditions without degradation, which is a vital consideration for riders who venture into diverse terrains. As per data from the International Cycling Research Institute, cyclists using ceramic components report a 30% longer lifespan for their bottom brackets, significantly minimizing replacement costs over time. As the cycling industry continues to evolve with advancements in materials and technology, understanding how to select the best ceramic bearing bottom bracket becomes imperative for maximizing performance and ensuring a superior riding experience. By considering factors such as compatibility, weight, and maintenance requirements, cyclists can make an informed choice that aligns with their specific needs and riding style.

Understanding Ceramic Bearings and Their Advantages

Ceramic bearings have gained popularity in the biking community due to their unique properties that enhance performance and durability. Unlike traditional steel bearings, ceramic bearings are made from advanced materials such as silicon nitride, which significantly reduces friction. This reduction in friction translates into smoother pedaling experiences and greater efficiency, allowing cyclists to achieve higher speeds with less effort. Additionally, ceramic bearings are more resistant to wear and tear, meaning they maintain their performance over a longer period, even under demanding conditions.

In addition to their performance advantages, ceramic bearings also offer superior corrosion resistance. This feature is particularly beneficial for cyclists who ride in varying weather conditions or in environments with high humidity. The non-porous nature of ceramic materials prevents moisture infiltration, mitigating the risk of rust and degradation that can plague steel counterparts. Overall, the choice of ceramic bearings can result in a cleaner, quieter ride, contributing to an improved biking experience. With these benefits in mind, understanding the role of ceramic bearings becomes essential for avid cyclists looking to optimize their set-up.

Evaluating Bottom Bracket Compatibility with Your Bike Frame

When it comes to selecting a ceramic bearing bottom bracket for your bike, ensuring compatibility with your bike frame is crucial. The bottom bracket serves as the connection point between the bike frame and the crankset, so understanding its specifications is key to a smooth installation and optimal performance. Start by checking the bottom bracket shell width and threading type on your frame. Common widths include 68mm and 73mm for standard road and mountain bikes, while threading can vary between English, Italian, and BB30 standards.

Additionally, consider the diameter of the bottom bracket shell, as this will determine which bearing type and size will fit properly. Some frames utilize a press-fit system, while others require threaded cups, so knowing your frame's requirements will guide your selection process. Furthermore, ensure that the compatibility extends to the crankset you plan to use, as different designs may necessitate specific bottom bracket options to achieve the best alignment and functionality. By taking these factors into account, you can confidently choose a ceramic bearing bottom bracket that not only fits properly but also enhances the overall riding experience.

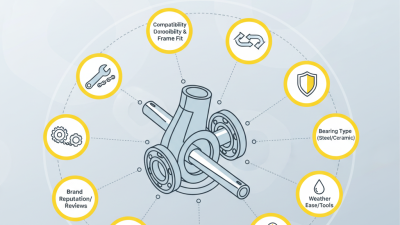

Factors to Consider When Choosing a Ceramic Bearing Bottom Bracket

When selecting a ceramic bearing bottom bracket for your bike, several critical factors must be considered to ensure optimal performance and compatibility. One of the primary aspects is the type of riding you intend to do. For instance, if you're an avid racer or plan to tackle uneven terrains, a bottom bracket designed to withstand extreme load conditions and deliver superior power transfer is essential. According to industry reports, ceramic bearings can reduce friction by up to 50% compared to traditional steel bearings, significantly enhancing efficiency and speed during rides.

Another crucial consideration is the material and construction of the bottom bracket. High-quality ceramic bearings are known for their durability and resistance to wear, which is vital in maintaining performance over time. Additionally, the shell type and width need to match your bike frame specifications. Reports from bike component manufacturers indicate that improper sizing can lead to compatibility issues and affect the overall riding experience. Furthermore, weighing the pros and cons of sealed versus open bearings can influence maintenance frequency, with sealed types often offering a better defense against dirt and moisture ingress. By paying attention to these factors, cyclists can select a premium ceramic bearing bottom bracket that complements their riding style and enhances their biking experience.

Comparing Different Brands and Models of Ceramic Bottom Brackets

When comparing different brands and models of ceramic bottom brackets, it's essential to consider several factors that can influence performance and longevity. The quality of the ceramic balls used in the bearings plays a significant role in reducing friction and enhancing overall efficiency. Brands may vary in their manufacturing processes, with some emphasizing precision engineering and rigorous testing to ensure durability. Therefore, examining the reputation of each brand for reliability and performance feedback from the cycling community can provide valuable insights.

Another critical aspect is compatibility with your bike frame and crankset. Different models may offer various installation types and shell widths, which could impact your choice based on your existing components. Additionally, while ceramic bearings can offer substantial benefits in terms of weight savings and smoother rides, it's worth weighing these advantages against your riding style and frequency. Users who ride regularly on varied terrains might prioritize durability alongside performance features, whereas those focused on racing might lean towards models optimized for speed. Thus, conducting thorough research on the specifications and user experiences of various ceramic bottom brackets can lead to a more informed decision.

How to Choose the Best Ceramic Bearing Bottom Bracket for Your Bike

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Material | Ceramic | Ceramic | Ceramic |

| Weight | 260g | 250g | 270g |

| Price | $120 | $135 | $110 |

| Compatibility | BB30, PF30 | BSA, PF30 | BB86, BSA |

| Seal Type | Double Seal | Single Seal | Double Seal |

| Lifespan | Up to 50,000 miles | Up to 40,000 miles | Up to 60,000 miles |

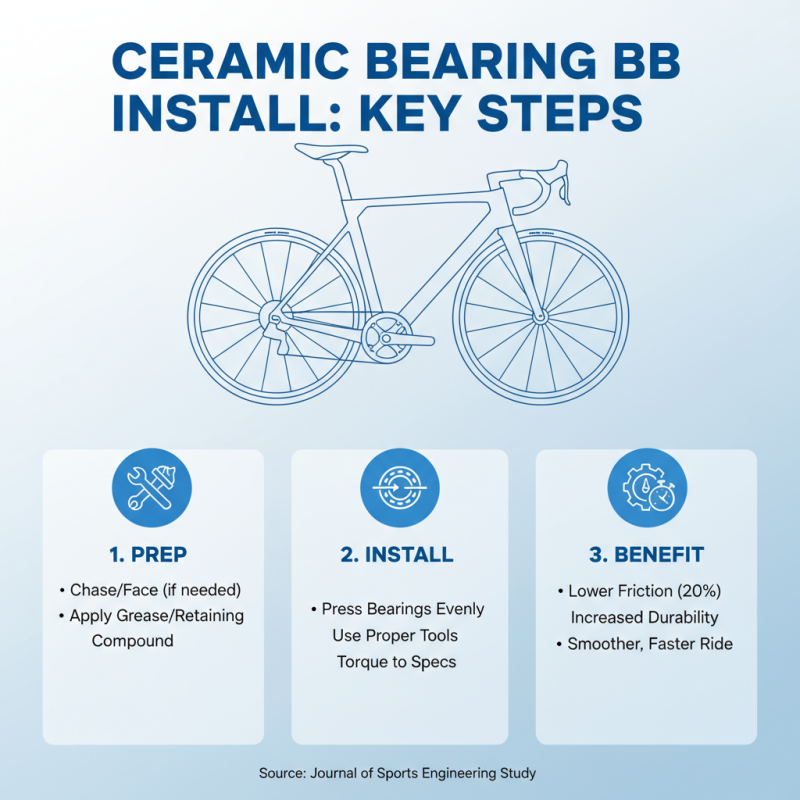

Installation Tips for Your New Ceramic Bearing Bottom Bracket

When installing a new ceramic bearing bottom bracket, certain considerations and steps can enhance performance and ensure longevity. Ceramic bearings are known for their low friction and durability, often providing a smoother ride. According to a study published in the Journal of Sports Engineering, ceramic bearings can reduce rolling resistance by up to 20%, making them a popular choice among cyclists looking for performance improvements.

One key installation tip is to ensure that the bottom bracket shell is clean and free of any debris before beginning the process. A clean surface helps create a proper seal and ensures the bearings function optimally. Additionally, consider using a torque wrench to secure the bottom bracket, as over-tightening can lead to premature wear or damage. A recommended torque setting for most bottom brackets ranges from 30 to 50 Nm, depending on the specifications of your frame and components.

Another useful tip is to apply a light layer of grease to the threads of the bottom bracket. This not only assists in easier installation but also aids in future removals. Regular maintenance is critical; experts suggest checking the condition of the bearings every six months or after extensive rides, especially in wet or muddy conditions, to maintain their performance and longevity. Following these steps will help ensure that your new ceramic bearing bottom bracket operates at its best, providing the efficiency and speed that every cycling enthusiast desires.

Related Posts

-

The Ultimate Guide to Choosing the Best Enduro Bottom Bracket for Your Bike

-

10 Best Bottom Bracket Threading Tools for Precision Bicycle Maintenance

-

Top 10 Tips for Choosing the Best BB86 Press Fit Bottom Bracket

-

2025's Top 10 73mm Bottom Brackets: Ultimate Guide for Cyclists

-

What is a Bottom Bracket Bike? Understanding Types and Choosing the Best

-

How to Choose the Best BB92 Bottom Bracket for Your Bike in 2025

This website uses cookies to ensure you get the best experience possible. Learn more.